Manufactured in Spokane, WA Since 1970

Marlin Storefront

Looff Carrousel - Riverfront Park, Spokane, WA

Storefront

System 40

System 45T Center Set

System 45T Center Set

1 3/4" x 4 1/2"

Frame members that are flush glazed with 3/16" or 1/4" glazing. This system is primarily used for vestibules or interior applications.

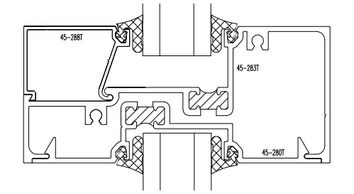

System 45T Center Set

System 45T Center Set

System 45T Center Set

2" x 4 1/2"

Frame members that are flush glazed with 1" insulated units or panels.

System 45T 6"

System 45T Center Set

System 45T Front Set

2 x 6"

Frame members that are flush glazed with 1" insulated units or panels.

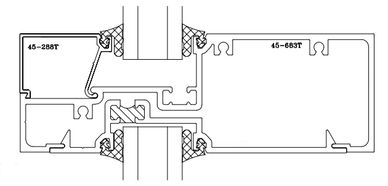

System 45T Front Set

System 45T Multi-Plane

System 45T Front Set

2 1/4" x 4 1/2"

Frame members with glass to the front. This system is typically glazed from the inside with 1" glazing. However, it can be glazed from the outside.

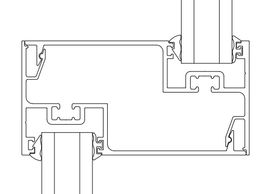

System 45T Multi-Plane

System 45T Multi-Plane

System 45T Multi-Plane

2 1/4" x 4 1/2"

Frame members with glass set to the front and back.

Specs & Details

Other Downloads

Specfications

GENERAL

Aluminum framing shall be Marlin System 40 or 45T thermally improved as manufactured by Marlin windows.

Marlin System 45T storefront shall have a AAMA 1502.7 condensation-resistance factor (CRF) of not less than 68 and a NFRC 500 condensation-resistance (CR) of not less than 35.

MATERIALS

All framing shall be aluminum extrusions of 6063-T5 or T6 alloy & temper. System 45T shall have a rigid polyurethane "thermal-barrier" as an integral contact between the interior and exterior aluminum sections including the door framing members utilizing a "thermal-break" door stop. Glazing gaskets shall be extruded E.P.D.M.

FINISH

Standard architectural Class II anodic color conforming to Aluminum Association AA-M12-C22-A34 for dark bronze or AA-M12-C22-A31 for clear anodized. (Architectural Class I and Class II anodic finishes and organic coatings available - specify).

CONSTRUCTION

System 40 aluminum framing shall have a 1 3/4" face and a depth of 4 1/2". System 45T framing shall have a 2" face width and a depth of 4 1/2" or 6" and provide for flush glazing without projecting stops. The system shall use a continuous sub sill. Optional thermally improved concealed project-out vent (Architect specify). Additional sight line shall not exceed 1 3/8". (Consult factory for hardware and screen options.) Maximum vent size 60" x 36".

PERFORMANCE

System 45T shall be tested in accordance with AAMA 501 and meet the requirements of ASTM E 283 for air infiltration, and ASTM E 331 for water penetration, and ASTM E 330 for structural performance. Deflection of mullions shall be limited to L/175 when subjected to the project design pressure of _____P.S.F. (Architect to specify).

System 45T NFRC Simulation test in accordance with ANSI/NFRC 100, Procedure for Determining Fenestration Product U-Factors (2014), ANSI/NFRC 200, Procedure for Determining Fenestration Product Solar Heat Gain Coefficients at Normal Incidence (2014), NFRC 500, Prodecure for Determining Fenestration Product Condensation Resistance Values (2014)

GLAZING

System 40 shall accommodate 3/16" or 1/4" glazing.

GLAZING

Marlin system 45T shall accommodate 1" glazing as required. Provisions for 1/4" glazing shall be accommodated by use of an adapter.

INSTALLATION

Glass and framing shall be installed straight, plumb, and level without twisting and securely anchored in place. All joints between framing and the building exterior shall be sealed to provide a watertight installation.

PROTECTION AND CLEANING

The General Contractor shall provide adequate protection of the aluminum and glass surfaces from damage by grinding compound, lime, acids, cement or other contaminants. The General Contractor shall be responsible for final cleaning.