Manufactured in Spokane, WA Since 1970

Lites & Insulated Units

Marlin Windows is a certified Vitro Fabricator.

- Units - We offer quick lead times on annealed units featuring Solarban 60 & Solarban 70 with aluminum spacer. Other glazing types, tempered, or units with warm-edge spacer have to be ordered, therefore, a slightly longer lead time.

- Lites: We offer a 2-day lead time on clear annealed lites, slightly longer for tempered lites and mirror.

Aluminum Spacer

Aluminum box spacer is a double perforated, lightweight, durable. spacer. The spacer is filled with desiccant to absorb any moisture in the insulted unit. The spacer is sealed to the glass with a butyl sealant and then a secondary sealant is used to cover the spacer.

While not quite as efficient as a warm edge spacer, many still prefer the classy look of aluminum spacer over the plastic and foam warm edge spacers.

- Spacer colors available: aluminum, bronze & black.

Warm Edge Spacers

"Warm edge" refers to the thermal conductivity of the spacer used to separate the lites of an insulating glass unit. If the spacer material is less conductive than convention aluminum, it is called warm edge.

Technoform (TGI) Spacer

TGI (Technoform Glass Inc) spacers are manufactured of stainless steel combined with a high quality plastic polypropylene as a strengthening and insulating material due to its low heat conductivity.

Technoform spacer allows only a very low heat transfer while guaranteeing extreme impermeability against gas diffusion and humidity. The result is a significant improvement in the thermal transmittance coefficient of a windows U-Value.

- Spacer colors available: light gray, dark gray, light brown, dark brown, black & white.

Super Spacer Tri-Seal

Architectural structural and captured glazing units.

Super spacer is a flexible, organic foam spacer that provides excellent perimeter insulation for sealed glazing units. It is an extruded, thermoset polymer structural spacer with integrally incorporated desiccants. Super Spacer is flexible and always returns to its original cured shape.

Super Spacer TriSeal features a continuous vapor barrier backing across the profiled back of the spacer, and is engineered to accept both a butyl primary seal and a silicone secondary seal.

- Spacer colors available: gray & black.

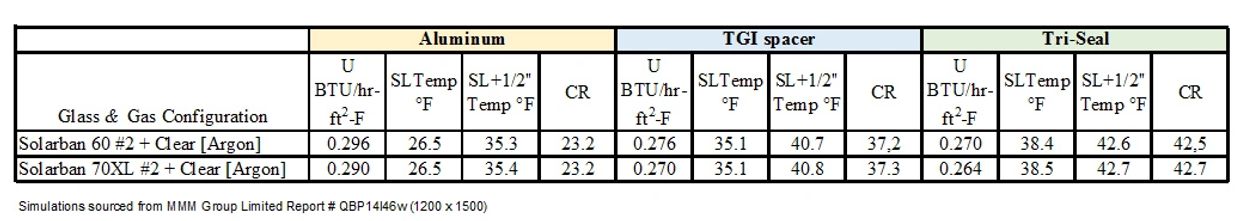

Spacer Comparison Simulation