Marlin System 60 Curtain Wall

Convention Center Expansion - Spokane, WA

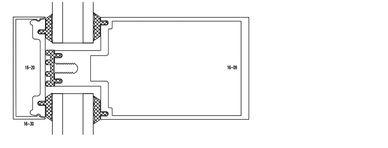

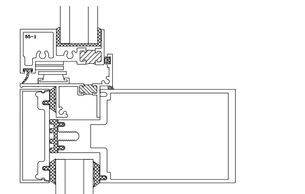

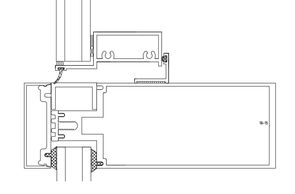

Marlin System 60 curtain wall combines the high performance of pressure wall design with high span capabilities. By utilizing a PVC thermal separator, to eliminate direct contact between interior and exterior aluminum sections, excellent thermal performance is achieved.

Steel reinforcing is available to fit into the rectangular mullion when extra strength is required. Horizontal members are attached to the vertical with shear anchor clips.

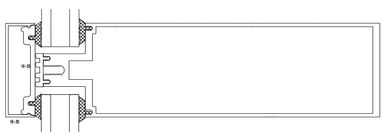

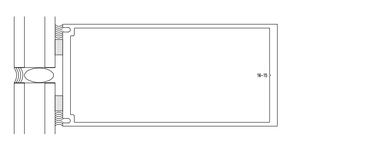

System 60 offers optional components to accommodate low profile vents, concealed vents, concealed butt-glaze vents, entrance doors, vestibule framing, interior partitions and sunshades.

Curtain Wall

2 1/2" x 5 3/4"

2 1/2" x 5 3/4"

2 1/2" x 5 3/4"

2 1/2" x 7 3/8"

2 1/2" x 5 3/4"

2 1/2" x 5 3/4"

2 1/2" x 10"

2 1/2" x 5 3/4"

2 1/2" x 10"

Butt Glaze

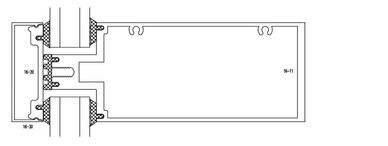

Low Profile Vent

2 1/2" x 10"

Low Profile Vent

Low Profile Vent

Low Profile Vent

Concealed Vent

Low Profile Vent

Low Profile Vent

Specs, & Details Download

More Downloads

Specifications

GENERAL

Aluminum framing shall be Marlin System 60 thermally improved as manufactured by Marlin windows.

MATERIALS

All framing shall be aluminum extrusions of 6063-T5 alloy & temper with a minimum wall thickness of .094". System 60 shall have a PVC thermal separator to eliminate contact between the interior and exterior sections. Glazing gaskets shall be extruded E.P.D.M. System shall accommodate vertical structural silicone butt glazing (Architect specify).

FINISH

Standard architectural Class II anodic color conforming to Aluminum Association AA-M12-C22-A34 for dark bronze or AA-M12-C22-A31 for clear anodized. (Architectural Class I and Class II anodic finishes and organic coatings available - specify).

CONSTRUCTION

Aluminum framing shall have a 2 1/2" face width and a depth of 10", 7 3/8" or 5 3/4" - (Architect to specify) and provide for flush glazing without projecting stops. Optional low profile vent (Architect to specify) Maximum vent 60" x 36".

OPTIONS

Incorporating standard Marlin project-out windows and all glass structural glazed vents.

Various beauty cap depths and profiles.

Fiber glass pressure plate in lieu of aluminum.

Steel reinforcing

Standard and custom sunshades.

SEISMIC

System shall be tested to withstand seismic racking without loss of integrity.

PERFORMANCE

System 60 test in accordance with AAMA 501 and meet the requirements of ASTM E 331 for water penetration, and ASTM E 330 for structural performance. Deflection of mullions shall be limited to L/175 when subjected to the project design pressure of _____P.S.F. (Architect to specify).

System 60 NFRC Simulation test in accordance with ANSI/NFRC 100, Procedure for Determining Fenestration Product U-Factors (2014), ANSI/NFRC 200, Procedure for Determining Fenestration Product Solar Heat Gain Coefficients at Normal Incidence (2014), NFRC 500, Prodecure for Determining Fenestration Product Condensation Resistance Values (2014)

GLAZING

Marlin system 60 shall accommodate 1" glazing as required. Provisions for 1/4" glazing shall be accommodated by use of an adapter.

INSTALLATION

Experienced workman in accordance with approved shop drawings shall install system 60. Glass and framing shall be installed straight, plumb, and level without twisting and securely anchored in place. All joints between framing and the building exterior shall be sealed to provide a watertight installation.

PROTECTION AND CLEANING

The General Contractor shall provide adequate protection of the aluminum and glass surfaces from damage by grinding compound, lime, acids, cement or other contaminants. The General Contractor shall be responsible for final cleaning.