Manufactured in Spokane, WA Since 1970

4500 Series Patio Door

Marlin Premium Aluminum Patio Doors - Built for Size & Style

Upgrade your space with our high-quality Marlin aluminum patio doors, designed for durability, sleek aesthetics, and expansive views.

Engineered for strength, we can craft them in exceptionally large sizes to bring the outdoors in—without compromising on performance.

Elevate your home or business with a seamless blend of design and functionality.

Handles

Contemporary

Olympus - Non-Locking

Olympus - Non-Locking

The sleek, modern design of these handles are sure to complement your door system.

Designed to accent today’s larger sized doors.

Extended bosses on inside and outside escutcheons to enhance handle stability.

Olympus - Non-Locking

Olympus - Non-Locking

Olympus - Non-Locking

This is a high-end product targeting high-end doors.

The larger overall size and round handle feels great in your hand. It does not look undersized on larger panels.

Olympus - Locking

Olympus - Non-Locking

Olympus - Locking

Center Thumb

Standard 5 Pin Cylinder Lock

Can be keyed-alike

A great solution for customers who want the best!

Hardware

Gemini Multi-Point Lock

Gemini Multi-Point Lock

Gemini Multi-Point Lock

Multi-Point Gemini lock is the ultimate in security.

Each hook is individually adjustable, enabling the installer to secure the lock properly in all situations. It incorporates a pin to prevent hook engagement unless the door is closed.

Tandem Roller Assembly

Gemini Multi-Point Lock

Gemini Multi-Point Lock

Rollers are equipped with full race, permanently lubricated radial ball bearings that are labyrinth-shielded to protect from dust and moisture.

Ball bearings are manufactured to provide the highest quality assemblies.

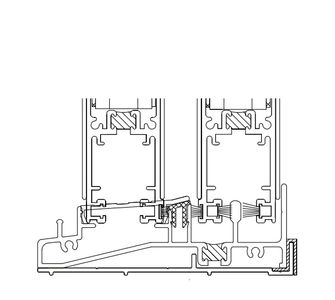

Residential - 1 1/2" Sill

Residential - 1 1/2" Sill

Residential - 1 1/2" Sill

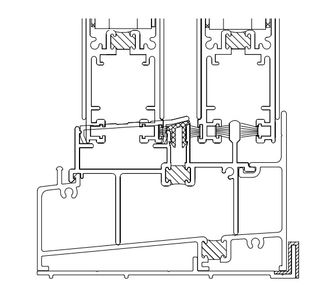

Commercial - 3" Sill

Residential - 1 1/2" Sill

Residential - 1 1/2" Sill

More Downloads

Specifications

GENERAL

Sliding Patio Door shall be series #4500, thermally improved as manufactured by Marlin Windows, Inc, and shall conform to AAMA/WDMA/CSA 101/I.S.2/A440-11 & AAMA/WDMA/CSA 101/I.S.2/A440-2017. The sliding patio door shall have a condensation resistance factor of 50.

MATERIALS

All frame and sash members shall be aluminum extrusions of 6063-T5 ot T6 alloy and temper. Frame and sash members shall have a rigid polyurethane "thermal barrier" as an integral part of the extrusion which eliminates all direct contact between interior and exterior aluminum sections.

FINISH

Standard architectural Class II anodic color conforming to Aluminum Association AA-M12-C22-A34 for dark bronze or AA-M12-C22-A31 for clear anodized. Also available in bronze or white painted finish conforming to AAMA 603.8. (Architectural Class I anodic finishes and other organic coatings available).

Custom paint to match virtually any color as selected by design teams

CONSTRUCTION

Framing members shall be 4 1/2" in depth. Frame and panel members shall be fabricated to form tight fitting joints. All joinery fastened securely with hardened steel self-tapping screws and sealed to prevent moisture and air infiltration. Sill members shall allow drainage of moisture to the exterior, but prevent direct inflow of wind, moisture and dirt. Sill track shall be extruded as an integral part of the sill member.

HARDWARE

Sliding panel shall incorporate adjustable steel ball bearing wheel assemblies at the bottom corners. Rigid vinyl guides shall be located on the top and bottom rails of the sliding panel to assure smooth operation. A pull handle/lock shall be attached to the lock stile. A 5-pin cylinder lock is optional at a slight additional cost. Optional stainless steel track recommended for heavy use.

WEATHERSTRIPPING

Sliding Panel shall have continuous weatherstripping of silicone treated wool pile incorporating a polypropylene fin to insure longer life with better resilience to wind and moisture infiltration. Weatherstripping shall extend around the entire perimeter of the sliding panel.

GLAZING

Marlin sliding patio door shall be glazed with 1" OA insulated glass. The panels shall be "marine" type glazed with a continuous vinyl channel gasket.

OPTIONAL SCREEN

Sliding screens shall be fabricated from 1 3/8" x 7/16" tubular roll-form aluminum, finish to match door. Screen cloth to be 18 x 16 fiberglass mesh held in aluminum screen frame with a tight-fitting continuous vinyl spline. (Heavy duty extruded screen frames are available - specify).

INSTALLATION

Door shall be installed straight, plumb, and level without twisting and securely anchored in place. Openings shall be properly prepared to provide sufficient space at jambs, head and sill to compensate for normal construction movement without affecting intended use.

PROTECTION AND CLEANING

The General Contractor shall provide adequate protection of the aluminum and glass surface from damage by grinding compound, lime, acids, cement or other contaminants. The General Contractor shall be responsible for final cleaning.