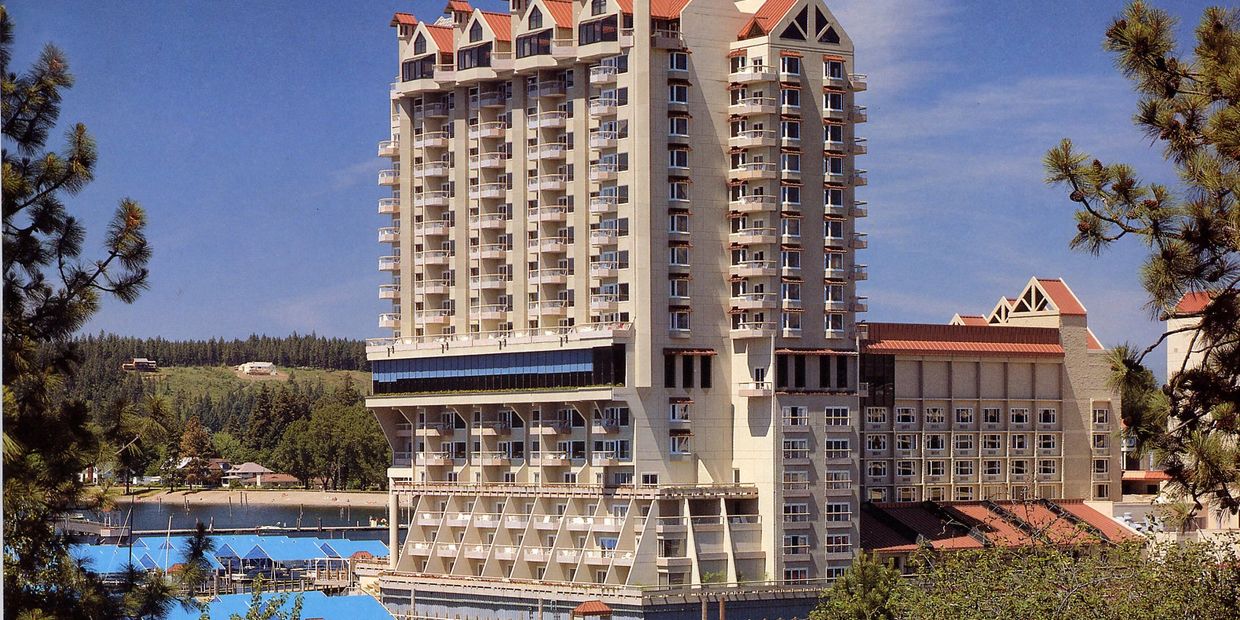

Manufactured in Spokane, WA Since 1970

Marlin Heavy Commercial Windows

Marlin Windows offers a full line of thermally efficient, heavy commercial window systems. By using a rigid polyurethane "thermal barrier" as an integral part of the window extrusions, these high performance windows will fulfill both your architectural and mechanical design requirements.

Each Marlin heavy commercial window is custom factory-fabricated using heavy duty Bronze Craft hardware and positive sealing weatherstripping to ensure long lasting superior performance. A complete line of accessory extrusions are available to meet various installation requirements.

Window Styles

7505 Fixed

7505 Awning/Hopper

7505 Casement

HC65

The overall window frame depth is 2 1/4". Standard glazing is 1" O.A.

Optional triple glazing is 1 7/16"

7505 Casement

7505 Awning/Hopper

7505 Casement

HC65

The overall window frame depth is 2 1/4". Standard glazing is 1" O.A. but will accept 1 7/16" triple glazing. Push out or roto crank operation are available.

Maximum vent size 36 x 66 / 30 x 72

7505 Awning/Hopper

7505 Awning/Hopper

7505 Horizontal/Vertical Pivot

HC65

The overall window frame depth is 2 1/4". Standard glazing is 1" O.A. but will accept 1 7/16" triple glazing. Push out or roto crank operation are available.

Maximum vent size 66 x 36 / 72 x 30

Roto minumum vent height for

7505 Horizontal/Vertical Pivot

7505 Horizontal/Vertical Pivot

7505 Horizontal/Vertical Pivot

HC45

The overall window frame depth is 2 1/4". Standard glazing is 1".

These windows accomodate large vent sizes with ease of washing exterior surface of glass.

24" minimum width.

7505 Internal Blinded Window

7505 Horizontal/Vertical Pivot

7505 Internal Blinded Window

Accepts 5/8" or 1" internal metal venetian blinds

16 standard colors

3500 HC Horizontal Slider

HC40

The overall window frame depth is 3 3/8".

Accepts 1" O.A. Glazing

Features adjustable stainless ball bearing rollers, positive cam latch.

3502 C55 Single Hung

C55

The overall window frame depth is 3 3/8".

Accepts 1" O.A. Glazing

Finishes

Marlin offers both anodized and painted finishes in any available specification or color. Because custom colored windows require extended lead times for color selection, sample submittal, and production as well as additional cost for setup and minimum order quantities, Marlin recommends this as an option for larger projects that allow for added time.

Marlin inventories the two most popular anodized finishes - dark bronze and clear anodized for all of our window series. We also stock black anodized for our fixed, casements & awnings. See color examples below.

T.I.E. Technology

Extruded aluminum has proven over time to be the best material for long lasting, low maintenance commercial windows. Marlin Windows uses high quality aluminum alloys best suited for window applications. All Marlin windows use extruded exterior glass stops to allow matching anodized finishes and provide extra strength under negative window loads.

Marlin thermally improved extrusions are accomplished by placing a specially designed cavity in the extrusion that is filled with a high density polyurethane. The bottom side of the cavity is then debridged with a saw, resulting in two separate extrusions that are held together by the polyurethane "thermal barrier". This provides a higher resistance to heat loss and condensation.

Hardware

Roto Hardware

Project-In Handle

Push-Out Handle

For project-out vent. Mounted at vent bottom, it allows for approximately 10" of opening. The double arm design also helps achieve corner pull-in and vent stability.

High-pressure die-cast zinc case, crank handle and knob. Hardened steel worm and gear arm.

Push-Out Handle

Project-In Handle

Push-Out Handle

Bronzecraft standard push/pull & locking handle for casement and project-out windows.

Project-In Handle

Project-In Handle

Project-In Handle

Bronzecraft push/pull locking handle for operation of in-swing vents.

Locking Handle

Locking Handle

Project-In Handle

Allows fors special key to lock or unlock.

Butt Hinge

Locking Handle

4-Bar Hinge

Cast bronze alloy exposed hinge is standard on casements with roto operators or push out hardware.

4-Bar Hinge

Locking Handle

4-Bar Hinge

Stainless steel self-balancing hinge. Standard for awnings, hoppers and inswing casements. Friction adjustment holds windows open at any position.

Friction Arm

Custodial Lock

Custodial Lock

Marlin's projected windows are balanced with either one or two heavy duty four bar friction hinges. Friction hinges are stainless steel and include a positive stop and an adjustable friction shoe.

Custodial Lock

Custodial Lock

Custodial Lock

Allows for control of vent operation. Requires special key to lock or unlock.

Pole End

Custodial Lock

Pole End Handle

For opening or closing clerestory or high-mounted windows.

Pole End Handle

Pole End Handle

Pole End Handle

For clerestory or high-mounted project-In vents

Cam Lock

Pole End Handle

Cam Lock

Standard on single hung's and horizontal sliders.

Positive thumb operated sweep cam lock provides maximum security

U-Values, Specs & Details

Other Downloads

Specfications - Series 7505

GENERAL

Projected, Casement, Fixed and Pivot windows shall be Marlin Series 7505 as manufactured by Marlin windows, and shall conform to AAMA/NWWDA -101-I.S.2-97 HC65 (HC45 for Pivot). Series 7505 shall have an AAMA 1503 CRF factor of not less than 56 and and NFRC 500 CR of not less than 33.

MATERIALS

All frame and sash members shall be aluminum extrusions of 6063-T5 alloy & temper with a minimum wall thickness of .094". Frame and sash members shall have a rigid polyurethane "thermal-barrier" as an integral part of the extrusion which eliminates all direct contact between interior and exterior aluminum sections. Glazing stops to be extruded aluminum with a minimum wall thickness of .050".

FINISH

Standard architectural Class II anodic color conforming to Aluminum Association AA-M12-C22-A34 for dark bronze or AA-M12-C22-A31 for clear anodize. (Architectural Class I anodic finishes and organic coatings available - specify).

CONSTRUCTION

Frame members shall be 2 1/4" or 3 3/8" in depth. Frame and vent corners shall be fabricated to form tight mitered joints. All intermediate frame members shall be coped to form tight butt joints where joined to perimeter members. All joinery fastened securely with stainless steel self-tapping screws and sealed to prevent moisture and air infiltration. Extruded aluminum glass stops shall be fabricated to form tight butt-joints. Maximum vent 66" x 36"

PROJECTED HARDWARE

Projected shall be balanced with two heavy duty four bar friction hinges. Hinges shall be of stainless steel, and include a positive stop and an adjustable friction shoe. Locking hardware shall consist of cam handle locks and surface strikes. Handle, base & strike housing shall be cast white bronze with burnished finish. Roto operators and underscreen bar operators are available (specify).

CASEMENT HARDWARE

Casement windows shall be supported by exposed hinges manufactured from cast bronze alloy and secured with concealed fasteners, or by heavy duty 4 bar concealed friction hinges (specify). Roto type operation with locking handles and concealed strikes shall be standard with exposed hinges. Other variations of hardware and finish available - consult factory.

PIVOT HARDWARE

Pivot vents shall rotate 180 degrees on cast white bronze pivots. Locking hardware shall consist of a project out handle one side and a project in handle the other side. Removable key custodial locks and limit devices are available options (specify).

WEATHERSTRIPPING

A compression seal shall run continuously around entire perimeter of ventilator and frame opening of ventilator to form a double seal.

GLAZING

Marlin Series 7505 windows shall accept glazing materials with nominal thickness of 1"and 11/2".

OPTIONAL SCREEN

Screen frames shall be fabricated from roll-form aluminum, finish to match window. Screen cloth to be 18 x 16 fiberglass mesh held in the aluminum screen frame with a tight fitting continuous vinyl spline.

INSTALLATION

Windows shall be installed straight, plumb, and level without twisting and securely anchored in place. Openings shall be properly prepared to provide sufficient space at jambs, head and sill to compensate for normal construction movement without affecting intended use.

PROTECTION AND CLEANING

The General Contractor shall provide adequate protection of the aluminum and glass surfaces from damage by grinding compound, lime, acids, cement or other contaminants. The General Contractor shall be responsible for final cleaning.